Liquid coolers

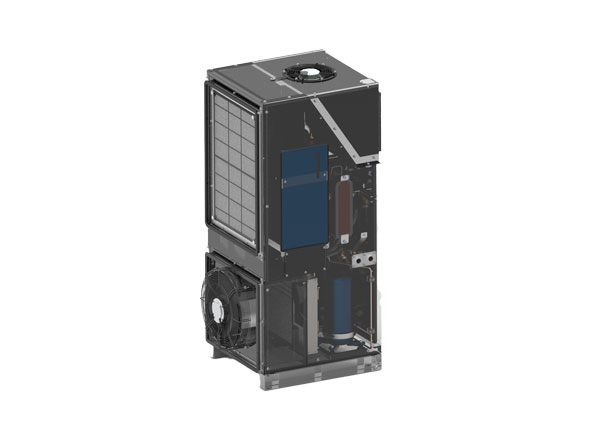

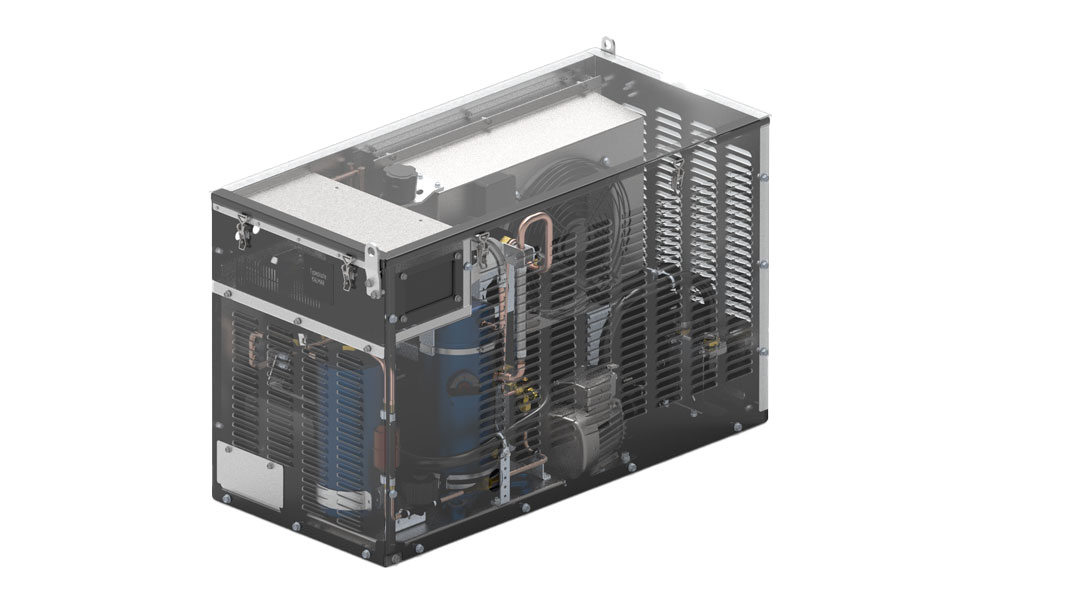

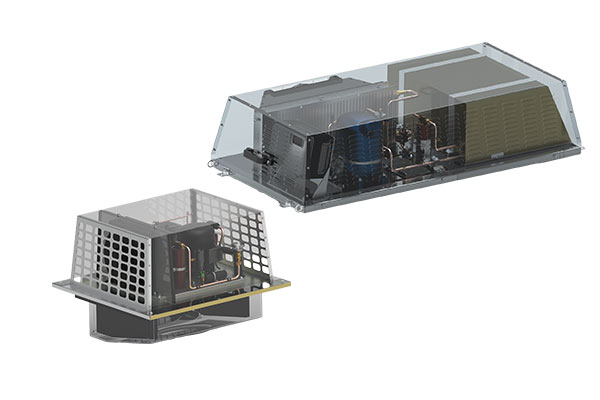

Cooling devices for separate spaces

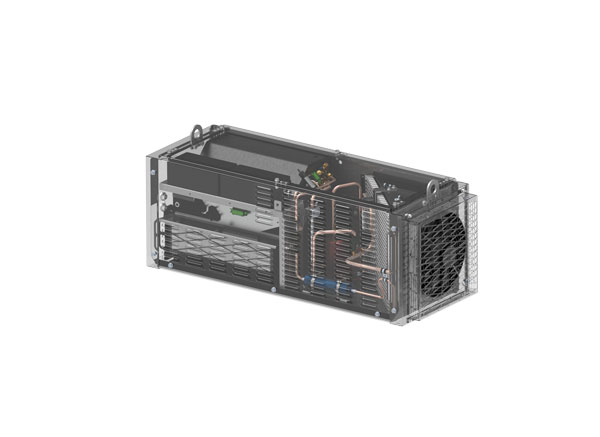

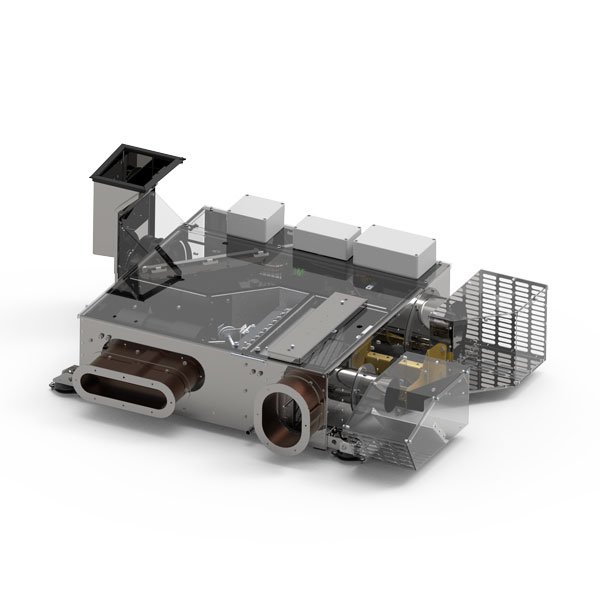

HVAC and air filtration systems for mobile equipment

Frequently asked questions

Does Lumikko manufacture refrigeration units for trucks?

No. Lumikko previously manufactured these units but sold the business in 2012. Since then, the business has been discontinued, but spare parts are supplied by BPW Kraatz Oy.

Does Lumikko manufacture freezers or freezing units?

No. However, this may be possible in special applications, such as environmental chambers.

What is the expected service life of the equipment?

In rail applications, the service life can reach up to 30 years. We support our systems throughout their entire lifecycle with maintenance and spare parts services.

Where is Lumikko located?

Lumikko Oy’s main factory and headquarters are located in Seinäjoki, Finland, at Lastausväylä 1, 60100 Seinäjoki.

Where can I order service for my cooling unit?

Get in touch with our service team: Contact details – Lumikko Huoltopalvelut Oy

What is the impact of the new F-gas regulation?

EU regulations are restricting the use of F-gases as refrigerants, and refrigeration technology is gradually transitioning toward refrigerants with lower climate impact as well as so-called natural refrigerants. Natural refrigerants such as propane, carbon dioxide, and ammonia have very low Global Warming Potential (GWP) values.

In 2025, Lumikko introduced its first product using natural refrigerants: the Lumikko BTMS.

Impacts:

- The prices and availability of F-gases are becoming more restricted, which may increase maintenance costs when high-GWP refrigerants are used.

- Leak inspections may be required more frequently for certain types of equipment.

- Refrigerant refilling may become more expensive as the cost of high-GWP refrigerants increases.

- Due to the restrictions, the service life of older equipment may be shortened, as they can only be serviced using recycled or reclaimed refrigerants.

- New equipment is more energy-efficient and more cost-effective over its lifecycle, even if the initial investment may be higher.

- Service providers are required to document refrigerant quantities, leaks, refills, and equipment maintenance in greater detail than before.

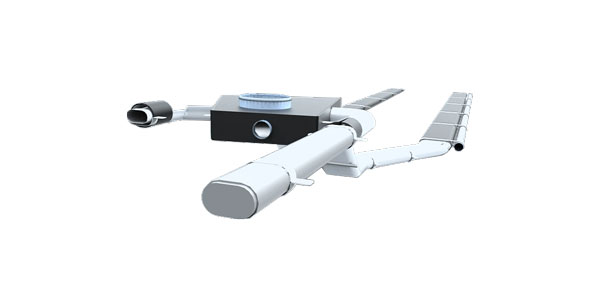

How does tram braking energy recovery system work?

During braking, electrical energy is directed to braking resistor units, where it is converted into heat and transferred to a circulating heat transfer fluid. This heat can then be used to support the tram’s heating system when needed.

The energy is stored in an energy storage unit integrated into the HVAC system and utilized when required.

Why do batteries need to be cooled?

In applications such as work machines, batteries are subjected to very high power demands, which can generate temperatures that are detrimental to battery health. Since batteries age faster at higher temperatures, effective cooling plays a key role in extending battery lifetime.

Why isn’t it advisable to choose a compressor that is oversized to ensure sufficient capacity?

An oversized compressor results in frequent unnecessary start-ups, causing faster component wear and increased operating costs.

Why does an air conditioning system dry the air?

Air conditioning removes moisture from the air by condensing water vapor during the cooling process. This reduces the amount of moisture in the air and lowers relative humidity.