Learn more about our production in the video below

Flexible and Scalable Production

Our production process is designed to accommodate the diverse needs of our customers and ensure rapid delivery times. Flexibility and scalability are key, particularly when manufacturing customized solutions, such as battery cooling for electric machinery or air conditioning systems for rail transport. Our production setup is designed to adapt seamlessly from prototype manufacturing to full-scale series production, allowing us to grow alongside our customers.

Production Lines and Specialized Expertise

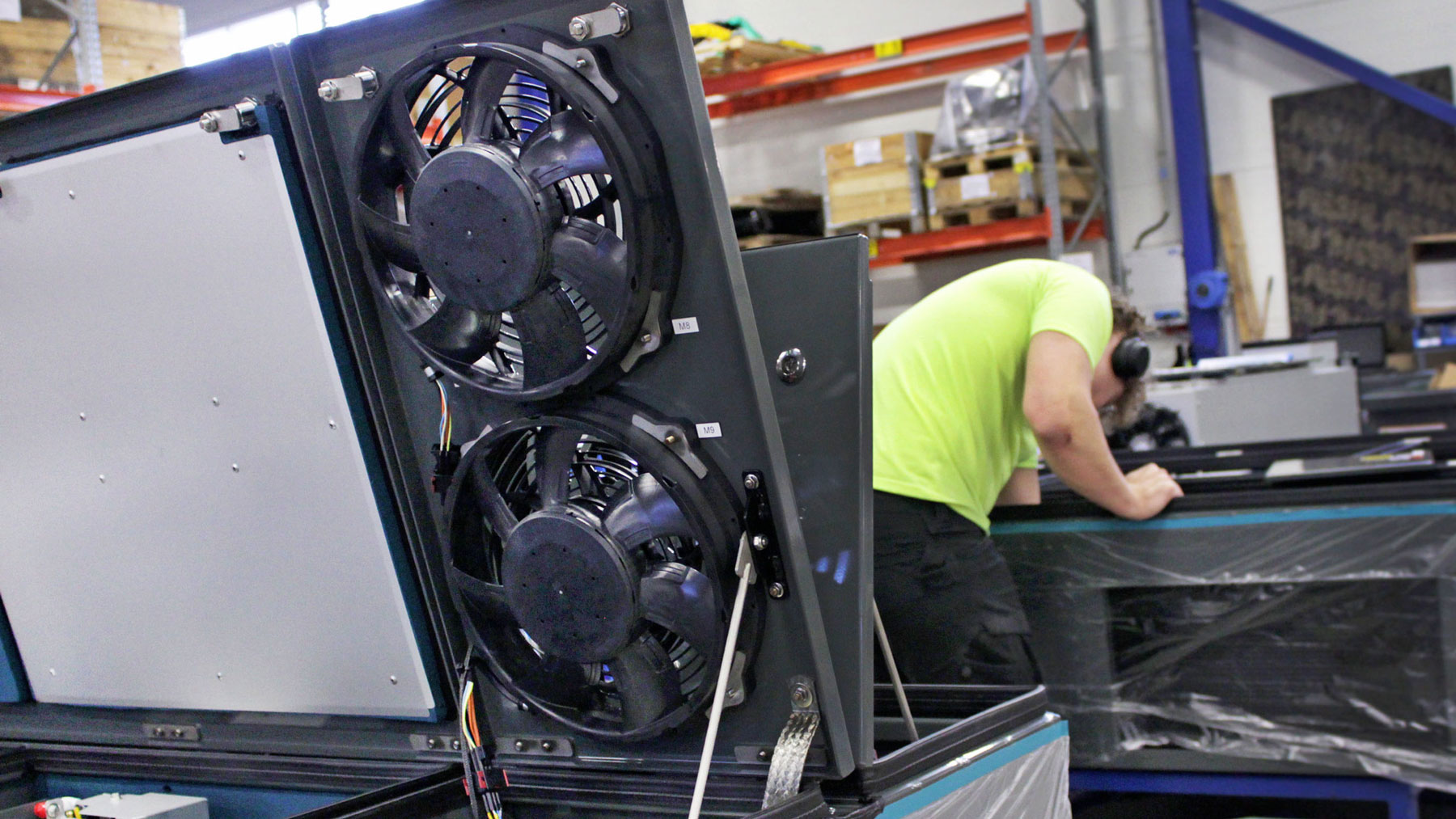

- Integration of Prototypes and Series Production: Lumikko’s production hall features dedicated areas for both prototype development and series production. This structure supports rapid product development and scalable manufacturing.

- Subassemblies and Assembly Lines: Our production cells are optimized for efficient subassembly processes, including electrical and mechanical subassemblies. These subassemblies feed into phased assembly lines where products are assembled, electrified, pressure tested, test-run, and finalized step-by-step.

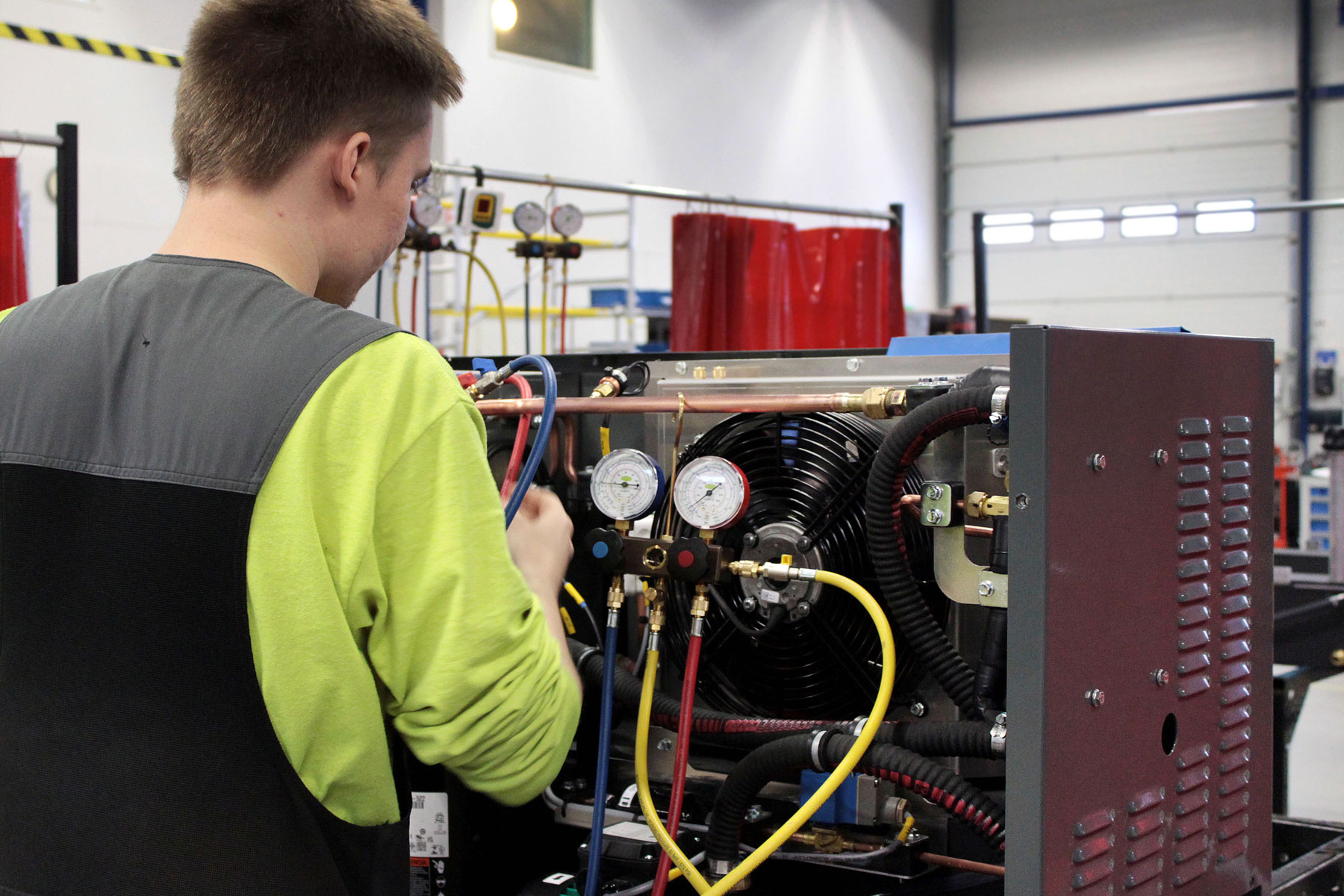

Quality Assurance and Pressure Testing

Every device manufactured by Lumikko undergoes rigorous quality assurance processes. Pressure testing and test runs ensure that the products meet all customer requirements and function reliably, even in extreme conditions. The cooling and liquid circuits of each device are pressure-tested, and their functional features are thoroughly examined.

Best Partner in Thermal Management Solutions

At Lumikko, our goal is to be the best partner in thermal management solutions. This commitment is reflected in every step of our production process, focusing on quality, delivery reliability, and speed, while also prioritizing employee well-being and a positive work environment.