Developing the future tram | Lyyli Living Lab

Lumikko Oy is involved in developing the future tram in the “Lyyli Living Lab” project led by Tampere Tramway Ltd. The project is carried out in cooperation with Škoda, the City of Tampere, Business Tampere, VTT and the University of Tampere. There are more than 20 companies involved.

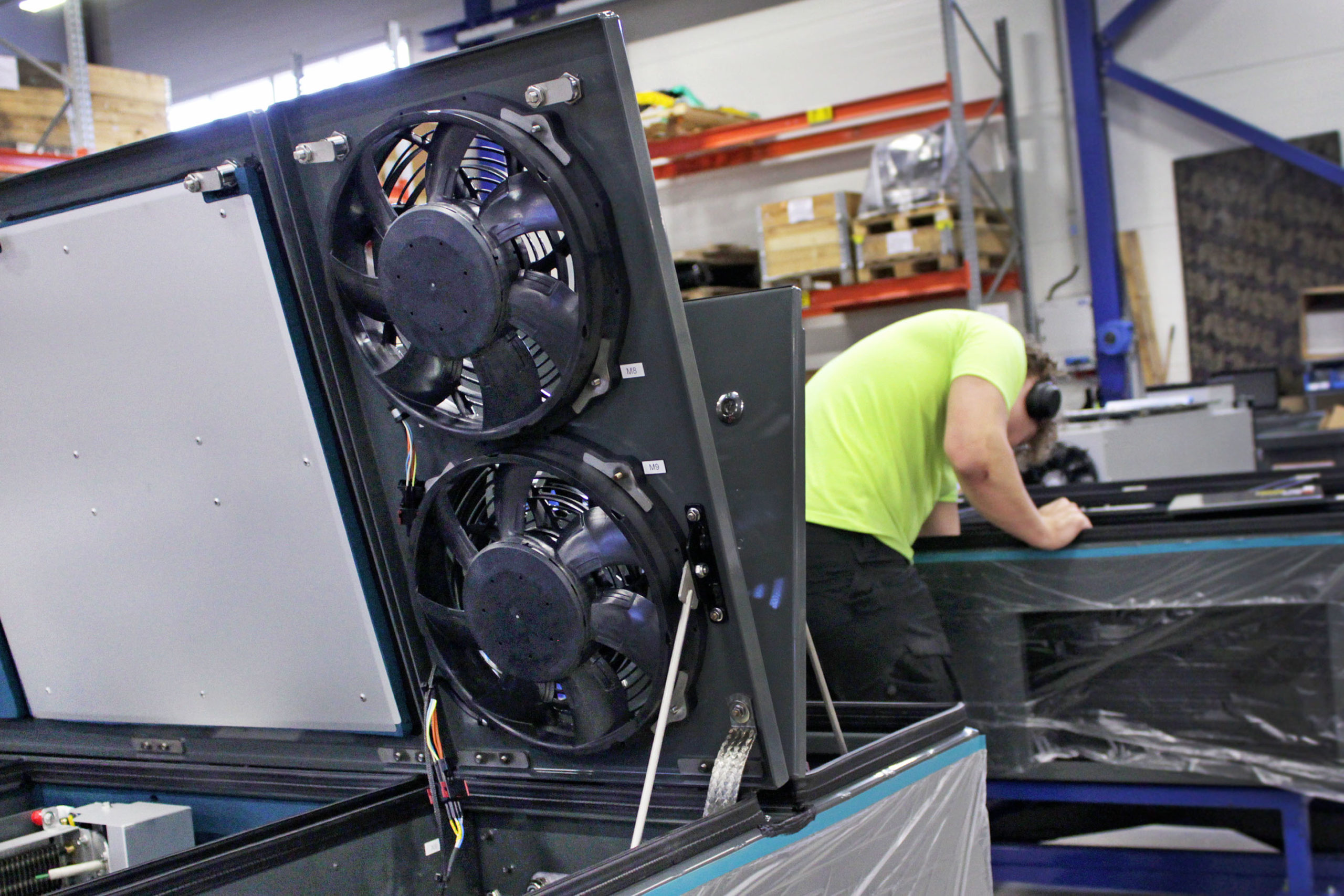

Lumikko Oy has been a pioneer in developing and implementing HVAC (Heating, Ventilation and Air Conditioning) and thermal management solutions for mobile equipment for over 50 years. The goals of carbon neutrality, congestion and space needs in urban areas have raised the development of public transport as one of the key priorities in the largest cities.

– Our product development history related to thermal management in mobile equipment, such as trains and trams, is long. With persistent work, we have become one of the leading experts in the field. In 1992, we designed and implemented the first air conditioning solutions for diesel train cabs. Today, Lumikko’s thermal management solutions can be found in almost all double-decker trains and trams operating in Finland, says Ville Saikkonen, Product Development Director of Lumikko Oy.

Opportunity for new innovations

In the Lyyli Living Lab test tram, Lumikko gets to test and develop technology that aims to improve the passenger experience through product development and innovation.

– For example, data collection on device performance, and predictive maintenance based on it, improve device functionality and extend service life. Based on the data obtained, we can also develop better thermal management and air quality solutions for our customers, Saikkonen says.

The main goal of the project is to enable new service and product experiments in a test tram operating in normal traffic.

– This is a unique development environment worldwide. We hope that it will generate concrete innovations, services and products that companies can bring to the market, says Ali Huttunen, Rolling Stock Manager of Tampere Tramway Ltd.

Regenerative braking system produces energy efficiency

Lumikko Oy’s regenerative braking system, developed in 2011, is in use in all Tampere Tram trams. There are currently 20 trams operating in Tampere.

The system allows the energy generated during braking to be regenerated and transferred to the heating of the passenger compartments as needed.

– According to calculations, in Tampere, one tram uses about 120,000 kWh of energy per year for heating. Braking energy is generated approximately 74,000 kWh per year. From this, one could calculate that with the braking energy produced by one tram, four large electrically heated houses could be heated for a year, Saikkonen illustrates.

Huttunen states that in tram rolling stock, HVAC solutions are basically the only way to utilize otherwise wasted braking energy.

– Energy efficiency is a very important issue. We are constantly looking for ways to improve it. In addition to braking energy recovery, all selected electrical components are inherently such that they consume as little energy as possible. This issue is handled by us and Lumikko in an advanced way. Huttunen considers Lumikko’s system a clear competitive advantage for the company.

Huttunen considers Lumikko’s system a clear competitive advantage for the company.

– Not all suppliers in the world have such a solution integrated into the HVAC system, which is important especially in northern conditions.

In the Lyyli test tram environment, more accurate information is obtained from the braking energy recovery system.

Saikkonen opens up that based on the data obtained, for example, the braking energy recovery percentage can be improved further by optimizing the control parameters.

– This way, more efficient braking energy recovery and heat transfer efficiency can be developed.

The goal is to offer the cleanest air in the world

The test tram also uses a new innovation, Lumikko’s “Viruskiller 2.0” filter system.

– It is a filter based on a special material. In test conditions, it has been able to remove 90 percent of even 0.3 micron particles from the inlet air, says Saikkonen.

The Lyyli test tram is an excellent platform for testing new innovations. The filter is coming to a wider test in a real environment in 2023.

– We do tests based on which we get information, for example, on how long the filtration performance lasts and how much its performance deteriorates over time. This helps us in product development and estimating the filter replacement interval.

Lumikko’s filter system development has required testing of different technologies persistently.

– We have tried, among other things, a solution based on UV light and electrical charging of particles. Its temporal filtration capacity did not meet our quality level, so now product development continues. Currently, we are satisfied with the option we have developed.

Saikkonen says that despite the name, it is not just about filtering viruses, although the topic is topical in the world.

– Filtering fine particles, i.e. air pollutants and dust, is an important aspect. The situation in Finland is not so bad, but in the world’s largest cities, the issue has a real impact. So we can say that we offer people clean air to breathe.

Huttunen says that new product innovations and their piloting opportunities are the most important task of the Lyyli Living Lab.

– Bringing new products to the market is always a risk. Testing in a real environment gives the opportunity for the next step in bringing concrete products and services to international markets as well.

Lyyli Living Lab is a unique open test environment for trams operating in a real environment worldwide. It enables the development of urban mobility solutions based on challenges in a real environment in cooperation with different actors. The whole is part of the TRUMS innovation cluster and SmartTrail Ecosystem project funded by Business Finland. The project will continue until the end of 2025. Read more about SmartRail Ecosystem. SmartRail Ecosystem

Read more on the topic: Local production and experience create added value

Explore Lumikko’s railway solutions.